The Kinemaniacs Story

When the Kinemaniacs team first formed, we embarked on our journey with a simple but audacious goal: To create a 6DOF motion platform capable of magnetic levitation.

Our solution is to limit the total available energy with capacitors – in an over-demand scenario, the system only has a fixed amount of energy per unit time available before it shuts down due to under voltage. Safety, in our journey, is never compromised.

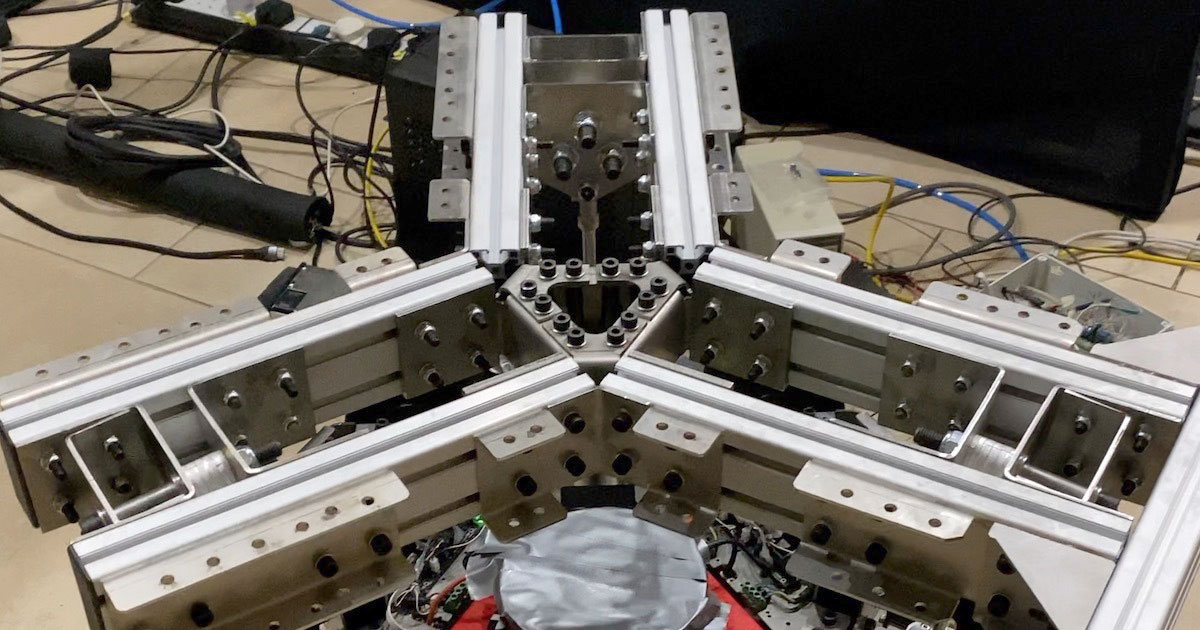

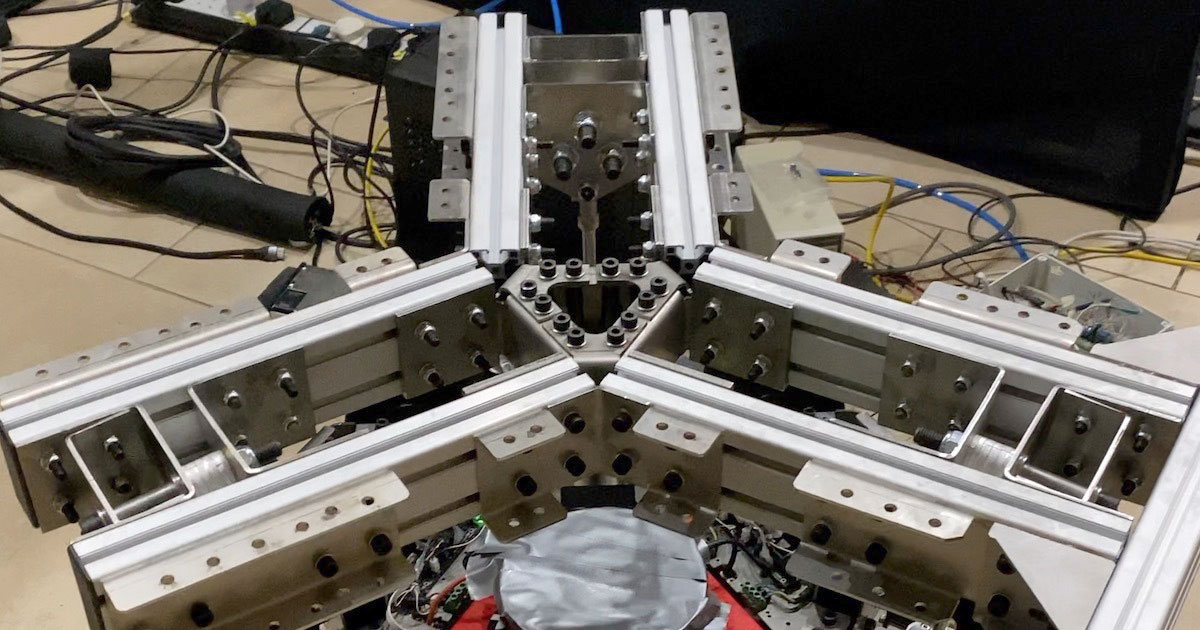

Onward then to the next significant leap in our adventure – Delora. Inspired by our successes with the ±5 inch hoverboard motors and learning from the mechanical stress issues on the motor axle, we decided it was time to scale up. The decision to use 10-inch custom-wound scooter motors, boasting torques of over 50Nm each, became the foundation for our first official prototype.

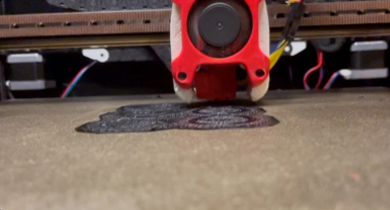

Captions

Captions 2

Captions 3

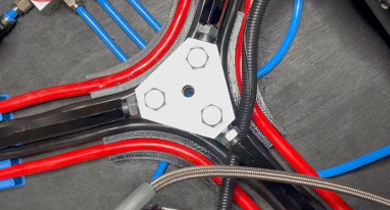

Powering Delora is a 3kW telecoms rectifier outputting 53.3V, buffered by an array of six 0.5F 63V large-format electrolytic capacitors from the concert audio industry. Configuring these into a single 3F capacitor made us realize that we had effectively built a Flux Capacitor – aptly named after the iconic device from “Back to the Future”. It looked and functioned much the same, with the three oDrives directly piping energy to and from the capacitor and BLDC flux coils.

Delora, in her full glory, showcased some rather impressive specs. We hit peak power at approximately 40kW with oDrive, but we realized that upgrading to 140kW was easily attainable by substituting oDrives with more powerful controllers from VESC Project. The move to the larger 10-inch motors allowed for a considerably bigger motion envelope:

- Surge 236mm

- Sway 218mm

- Heave 196mm

- Yaw 23.8 degrees

- Pitch 21.5 degrees

- Roll 22.3 degrees

Captions

Captions 2

Captions 3

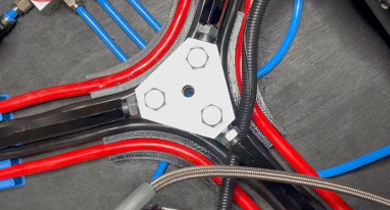

In terms of mechanical refinement, we integrated our previously external ballast tanks into a single 3-cylinder pneumatic piston with an integrated 2-chamber ballast tank in the lower half of the piston. This design, combined with a larger ballast volume, allows for a more evenly distributed force throughout the piston’s travel. Delora was designed to handle a total payload of 500kg, thus we opted for larger 50mm pistons to compensate.

The path to innovation is never a straight line, but each step brings us closer to our goal.